1. Scope

This specification applies to CR1632 of 3V lithium battery made by Changzhou Anyida Power Source Technology CO., LTD.

Meet the standards of GB8897-2008 and EU directive 2006/66 / EC.

2. Technical parameters

|

Electrochemical System

|

Lithium manganese dioxide/organic electrolytes

|

|

Nominal Voltage

|

3V

|

|

Nominal Capacity (Continuous Discharging Under 30kΩ load to 2.0V End-Voltage at 20℃)

|

120mAh

|

|

Operating temperature range

|

-20℃~70℃

|

|

|

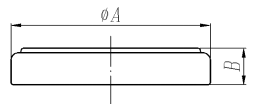

diameter(A)

|

16.0(-0.3)mm

|

|

|

height(B)

|

3.2(-0.3)mm

|

|

Mass

|

Approx2.0g

|

|

Appearance and poles

|

Appearance should be a smooth, clear mark, no deformation, rust, and leakage

|

|

Minimum Average Discharge Time(30kΩ)

|

Initial test (New battery in 60 days)

|

1230h

|

|

|

After 12 months

|

1100h

|

|

Open Voltage

|

Initial test (New battery in 60 days)

|

3.10V-3.45V

|

|

|

After 12 months

|

3.10V-3.45V

|

|

Closed Circuit Voltage(30kΩ)

|

Initial test (New battery in 60 days)

|

3.10V-3.45V

|

|

|

After 12 months

|

3.00V-3.45V

|

|

Leakage Characteristics (Over discharge)

|

No Leakage

|

3. Test Method

|

|

Item

|

Condition

|

|

1

|

Dimensions

|

When measured with vernier calipers which precision is up 0.02mm. to avoid short circuits, paste on one insulation material on one end of the vernier calipers.

|

|

2

|

Open Voltage

|

the precision of the multimeter is not lower than 0.25%, intel resistance is bigger than 1MΩ

|

|

3

|

Instant short-circuit current

|

When testing with multimeters, do not surpass 0.5 seconds each time, and avoid duplicating tests, if needed once more, the time gap should be above half an hour

|

|

4

|

Appearance

|

The appearance of batteries shall be inspected by visual means.

|

|

5

|

Min time of discharge

|

Lay aside above 8 hours at a temperature of 20±2℃ and under the humidity of 60±15% conditions, with the condition that Resistance is 30kΩ, and end-point voltage is 2.0V. The new battery (Initial stage) should be tested in 60 days after production. The old battery (Delayed for 12 months) should be tested in 14 days after the storage period.

|

|

6

|

Over-discharge Characteristics

|

Take nine batteries at a temperature of 20±2℃ and under a humidity of 60±15% conditions, with the condition that Resistance is 30kΩ, and end-point voltage is 1.2V. visual test.

|

4. Acceptance rule

4.1 Delivery inspection for each shipment quantity for a test batch。

4.2 Delivery inspection using GB2828.1-2003 Normal inspection sampling plan at a time, inspection item、inspection level(IL)、acceptance quality limit(AQL)According to the provisions of the table below。

|

|

Check item

|

IL

|

AQL

|

|

1

|

Dimensions

|

I

|

0.25

|

|

2

|

Open Voltage

|

|

0.25

|

|

3

|

Appearance

|

Ⅱ

|

0.25

|

5. Important Notes(Warranty)

5.1 No swallowing

Keep the battery out of reach of children. Never put batteries in your mouth. If ingested, immediately seek medical attention.

5.2 No recharging

Forbid using any other power supply to charge the battery. Recharging can to producing gas and internal short circuits, causing cell deformation, leakage, overheating, explosion, or fire.

5.3 Do Not Dispose In Fire

The lithium will be melted when disposed of in a fire.

5.4 Do Not Disassemble

Do not disassemble the battery or it will cause damage to the gasket or the separator, deformation, leakage, overheating, explosion, or firing will happen.

5.5 Insert Batteries Correctly

Depending on the application device, incorrect insertion of batteries, with positive(+) and negative(-) poles reversed, may result in short circuits and the risk of heat generation, fire, or explosion.

5.6 Do Not Short-circuit

Do Not Short-circuit. Do not keep or store the battery with metal or it will cause deformation, leakage, overheating, explosion, or firing.

Do not take several pieces of batteries from the packing box at one time or stock mixed, it can to deformation, leakage, over-heat, or firing.

5.7 Do Not Mix Different Types Of Batteries

For some applications, mixing different types of batteries, or new and old batteries, can cause over-discharge due to differences in voltage and electrical capacities. This may to the risk of swelling or explosion.

5.8 Do Not Weld Pin Or Wire Directly On The Battery

The lithium will melt when welding or cause damage to the insulation material. This will to deformation, overheating, explosion, or firing. If a weld is needed, please contact Daily-max or a professional welder.

6. Cautions

6.1 Shaking、jumbling、Scatters or trampled batteries, may cause short circuits, heat generation, fire, or explosion.

6.2 Install batteries, please be careful when operating, don't let the battery come into contact with metal objects, which could make the battery short circuit.

6.3 Select suitable batteries as per the operation instructions.

6.4 Do not use or store the batteries in high-temp places like exposure to sunshine or in a car which in burning hot, will to deformation, leakage, over-heat, explosion, or firing.

6.5 Do not let the battery contact water or store it in a wet environment or it will cause rust, deformation, leakage, over-heat, explosion, or firing.

6.6 The voltage may be lower than the target one by bad contact so pls keep 2N contact pressure.

6.7 If you have any questions please get in touch with Anyida.

7. Storage Environment

The storage environment should be clean, cool, and dry, ventilation, should not be close to high or high moisture, the environment temp should be 0℃-30℃, and RH not exceed 75%.

8. Marking and Packing

8.1 Sign Of Positive Pole

Different brands can be as customers’ requests.

8.2 Date Code(Date code is selective and need to pay extra charge)

If customers need a date code as IEC standard with 2 words, the one expresses year by 0-9, the second one expresses Jan-Sep by 1-9, O, Y, Z means Oct-Dec.

Examples:01 means manufactured in Jan-2010; 0O means manufactured in Oct-2020;

0Y means manufactured in Nov-2010; 0Z means manufactured in Dec-2020。

Different date codes can be made.

8.3 Packing

Each 20pcs in a PVC tray, 25 trays(500pcs) be packed by PVC film, 6 small packages in one inner box, and 2 inner boxes(6000pcs) in an outer carton.

* If the batteries need to be with pins, the packing will be changed by product appearance.

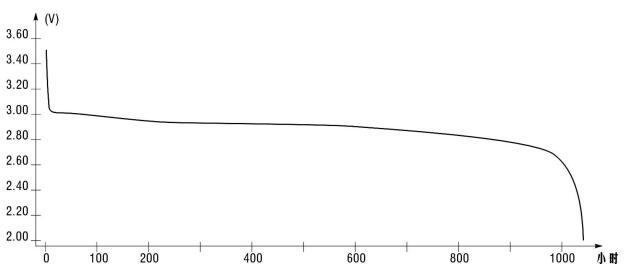

9. Discharge characteristics

With the progress of product technology, and technical parameters, the specification will be updated too, please contact Anyida for the latest specification.